Reverse Osmosis Desalination

Importance of Desalination

Around 70% of the earth’s surface is covered in water, but only 2.5% of that is fresh water and roughly 70% of that fresh water is captured as ice in the polar caps and glaciers. This means that only 0.75% of all water on earth is left for usage by humans. Approximately 2.2 billion people live without a secure supply of water, which makes about 27% of the population. Given that water is the foundation of life on earth this is a tragic statistic. Innovations for fresh water solutions are needed more than ever. Approaches like desalination aim for the 97.5% of unusable seawater as a new source of fresh water.

Figure 1: diagram of water distribution on earth

Reverse Osmosis (RO) Process

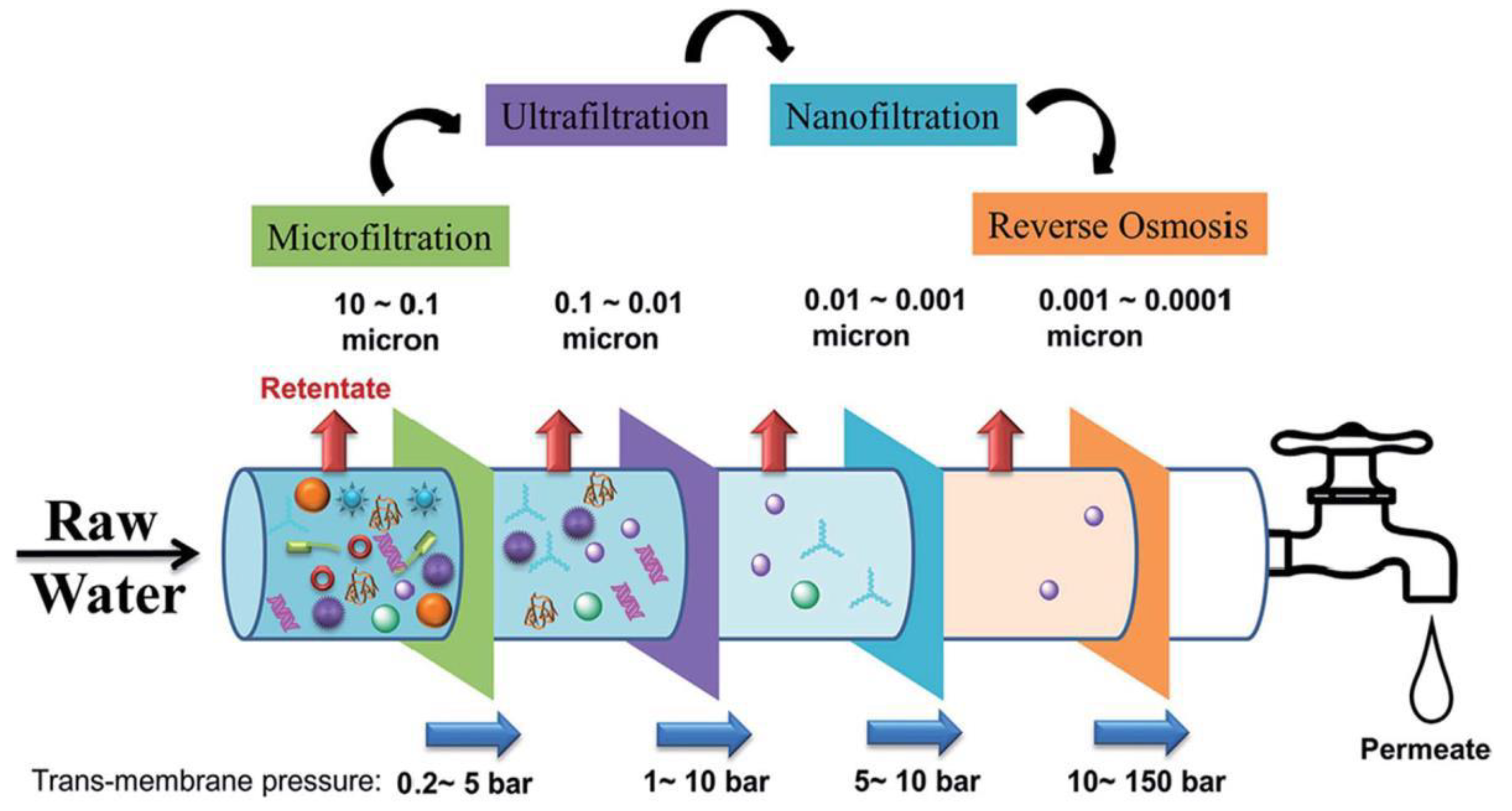

The process of desalination describes the separation of mineral components in saline water. To desalinate the seawater, the salt molecules have to get filtrated from the water. Previously to this, bigger molecules and particles have to be removed through various stages of filtration and then lastly the reverse osmosis takes place. It uses a semi-permeable membrane to filter out molecules the size of 0.1 – 1 nm. The results of seawater reverse osmosis are brine and permeate.

Figure 2: stages of filtration for reverse osmosis

Figure 3: breakdown of particles in figure 2

This type of separation is called reverse osmosis, because in order to work, it has to overcome the osmotic pressure. Osmosis is a natural process that occurs when two solutions in a closed environment containing different concentrations of solute are separated by a semi-permeable membrane, that holds back solute but not solvent, an imbalance of chemical potential occurs. The solution with a lower concentration of solute has a higher chemical potential than the higher concentrated solution. Water molecules will pass through the membrane to reach equilibrium of chemical potential. Due to being in a closed environment, the increase in volume of the solution with the higher concentration of solute results in an increase of pressure – osmotic pressure.

Figure 4: osmosis in a -shaped tube

For the separation of seawater (typically 35,000 ppm, 20°C) into brine and permeate, the osmotic pressure of 27 bar has to be overcome to prevent the inward flow of pure permeate across the membrane. The brine is retained on the pressurized side of the membrane while the purified permeate passes to the other side. This is done with crossflow filtration in contrast to dead-end filtration, where the filter at the end of a pipe would quickly be blocked by build-up solute.

Figure 5: cross section of crossflow filtration

Reverse Osmosis (RO) Desalination

Reverse Osmosis Desalination is one of the main methods of desalination and the most used for smaller and medium sized plants, due to the prompt availability and constant flow of pure water once the plant is installed. Thanks to the improvement of energy consumption on this matter it became more and more popular in recent years. Still, improvements in the current technologies are needed to make it a more accessible method to source drinking water. New technologies that reduce energy consumption will help to achieve a broader availability.

Resales Solutions for Seawater Desalination

The SALINO® Pressure Center revolutionizes seawater desalination by reverse osmosis in a worldwide unique way. Its compact design consisting of a 4-in-1 technology makes it extremely space-saving and therefore perfect for decentralized use in containerized systems. It combines high-pressure pump, energy recovering device, booster pump and electric motor in one single unit.

Other RO plants need more components than the SALINO® Pressure Center because they use a motor more to power an additional booster pump that sustains the needed pressure. These motor and pump are either directly hooked (figure 7) to the isobaric pressure exchanger or are connected in series (figure 6) to it.

Figure 6: model of RO plant with booster pump in series to pressure exchanger

Figure 7: model of RO plant with booster pump connected to pressure exchanger

The pressure exchanger (PE) of the SALINO® Pressure Center doubles as an energy recovery device (ERD) which increases the efficiency of the motor.

Figure 8: model of RO plant with SALINO® Pressure Center

In the first half, low pressure feed water (colored in light blue) flows into the pressure exchanger. It gets pushed into axial pistons that rotate on an angled plate (video: 01:35), which compresses the pistons and the feed water in it. Because of the relation

decreasing the volume of the feed water increases its pressure (colored in purple) given that this is an isothermal process. The high pressure feed water created during this is now led to the RO membrane.

In the second half after the RO process, high pressure brine (purple) from the RO membrane flows into the energy recovery device (video: 01:55). The RO process has a recovery rate of 45%, which means that 45% of the volume of the feed water directed to the RO membrane crosses said membrane and becomes fresh water. The remaining 55% are led back into the energy recovery device. There the pressure exchanging procedure is repeated backwards. High pressure brine is pumped into axial pistons rotating on an angled plate. The angle in the ERD is smaller than the one in the PE, proportionally to the total volume of fluid. The pistons filled with high pressure brine get decompressed resulting in low pressure brine flowing out of the ERD.

The ERD gives back up to 70% of the power initially put into by the motor (video: 02:15) making it very efficient.