Inline circulation pumps

Inline circulation pumps for systems in building services and industry

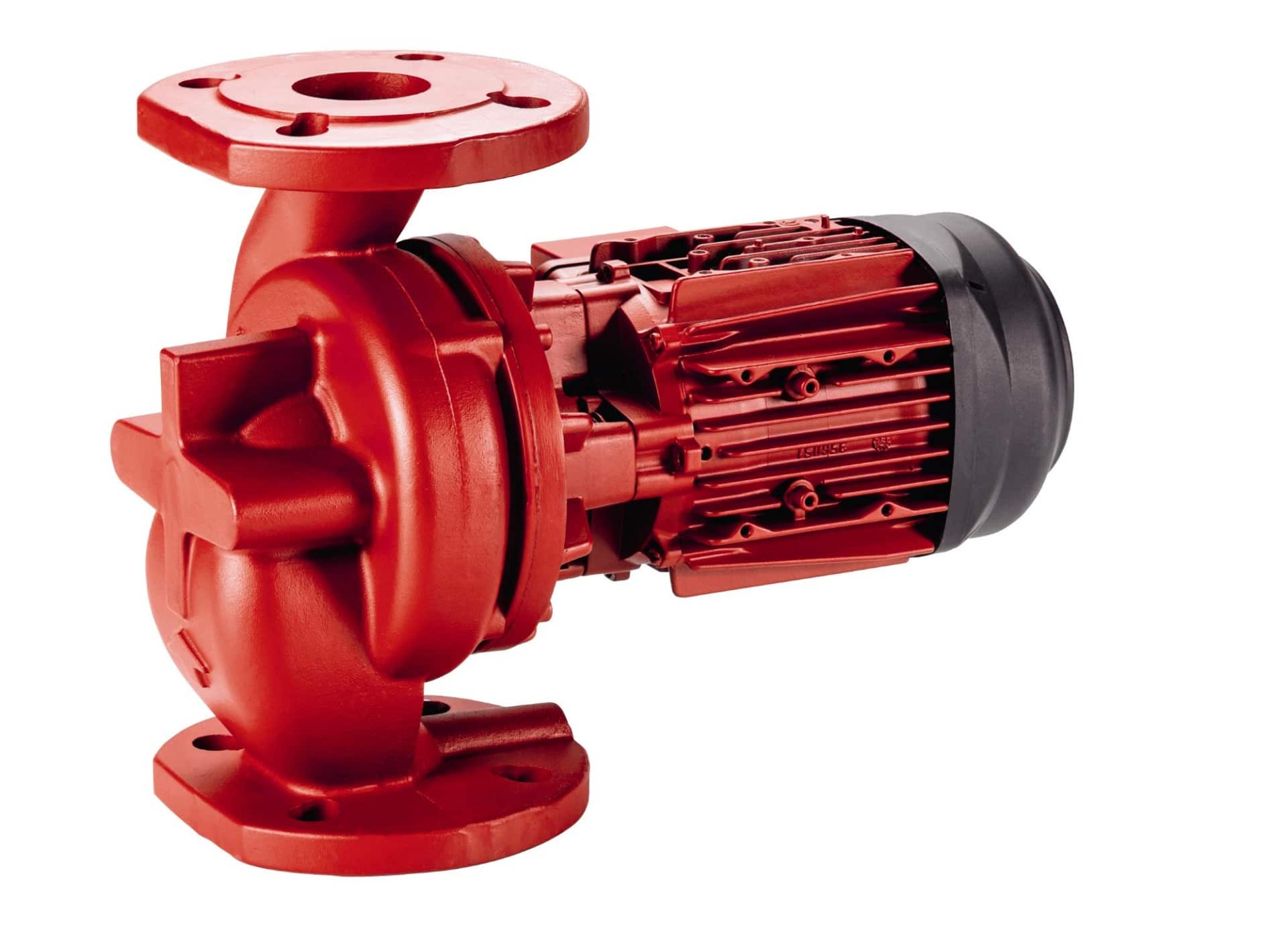

Design of inline circulation pumps

Inline circulation pumps are available as so-called dry-running pumps with a mechanical seal and as wet-rotor pumps glandless pumps. The suction and discharge connections usually have the same nominal widths and are located on the same axis. This means that the inline pump can be installed directly in the pipeline, which is why they are also referred to as pipeline pumps. Inline pumps with a mechanical seal are available with an integrated motor, whereby the motor shaft is extended and also serves as the pump shaft, and as a close-coupled block design, whereby a standard motor with a flange is connected to the pressure cover via a bellhousing and the motor shaft is connected to the pump shaft via a rigid coupling. They are used as circulation pumps in closed systems and for pumping clean and aggressive liquids.

Find inline circulation pumps now

Inline circulation pumps in various designs

Thanks to its compact design, the inline pump has become particularly popular in building services engineering.

Many inline pump models can also be installed both horizontally and vertically, offering a wide range of possible applications. Inline pumps with high delivery heads are also used in more complex building structures, such as high-rise buildings – we offer these individually under “Multistage pumps” and as a system under “Pressure boosting systems”.

Some models are available in both single and twin versions. Depending on the application and the pressure level to be generated, you can choose between a single-stage and a multi-stage inline pump.

Inline centrifugal pumps are available as dry-running pumps with a seal and as “wet-rotor pumps”.

Different types of inline circulation pumps

Inline pumps

Single-stage volute casing pumps in an inline design with a close-coupled design. The drive, a flanged standard motor, is connected to the pump casing via a lantern – and the drive shaft is connected to the pump shaft via a short rigid coupling. These pumps are available for both horizontal and vertical installation – and are used for pumping water, heat or cold conductive media and oily liquids. High performance, low space requirements and flexible installation options speak for the use of inline pumps.

Our product series:

– KSB Trialine

– KSB Etaline

– KSB Etaline-L

– WILO IP-E

– WILO TOP

– WILO Stratos GIGA

Inline twin pumps

Single-stage volute casing pumps in inline design with a twin block construction. The drives, two flanged standard motors, are connected to the pump casing via lanterns – and each drive shaft is connected to the pump shaft via a short rigid coupling. These pumps are available for both horizontal and vertical installation – and are used for pumping water, heat or cold conductive media and oily liquids.

Our product series:

– KSB Trialine-Z

– KSB Etaline-Z

– KSB Etaline-DL

– WILO VeroTwin

Vertical inline pumps

Single-stage volute casing pumps in inline design with bearing bracket or block design. The drive, a flanged standard motor, is connected to the pump housing via a bellhousing – and the drive shaft is connected to the pump shaft by a flexible coupling. These pumps are only available for vertical installation. High performance, low space requirements and flexible installation options determine the use of inline pumps.

The suction and discharge connections have different nominal diameters but are located on one axis and are used for pumping water, seawater, brackish water, brine, hot water, heat or cold conductive media and oily liquids as well as fuels.

Our product series:

– KSB ILN

– KSB ILNC

– KSB Etaline-R

– WILO Cronoline IL

Application description

Inline pumps are used in building cooling and heating circuits as well as in municipal systems for district heating and in industrial and process engineering for various circulation circuits. These pumps are suitable for a limited number of pumped media and a limited temperature range, which is why the range of different materials is relatively limited.

Main application area:

▪ Domestic hot water systems

▪ Heating systems

▪ Industrial circulation systems

▪ Air conditioning systems

▪ Cooling circuits

▪ Water supply systems

Inline twin pumps are used in building cooling and heating circuits as well as in municipal systems for district heating and in industrial and process engineering for various circulation circuits. To extend the service life of the pumps, they are often used in alternating mode. These pumps are suitable for a limited number of pumped media and a limited temperature range, which is why there is a limited choice of materials for impellers and mechanical seals.

Main application area:

▪ Domestic hot water systems

▪ Heating systems

▪ Industrial circulation systems

▪ Air conditioning systems

▪ Cooling circuits

▪ Water supply systems

▪ Wasserversorgungsanlagen

These pumps are available in various materials such as gray cast iron, bronze, aluminum-bronze and duplex. Due to the small space requirement, the high performance variance and the different casing, impeller and seal materials, these pumps are particularly suitable for use on ships or for other marine applications. They are also frequently used in industry.

Main application area:

▪ Heating systems

▪ Cooling circuits

▪ Air conditioning systems

▪ Marine applications

▪ Service water systems

▪ Water supply systems

▪ Cleaning systems

▪ Industrial circulation systems

How do I find the right inline circulation pump at Abacus Resale?

Pump type selection: Select “Inline circulation pumps”

Operating data: Enter

• the volume flow in “m³/h” for Q

• for H, enter the delivery head in “m”

• Click on “Results”

Too many search results? Refine your search

• Select the desired size

Pumpenart vom Spezialisten

Ihre Ansprechpartner

Application advice and configuration of pumps and systems

Application advice and configuration of pumps and systems